Overview:

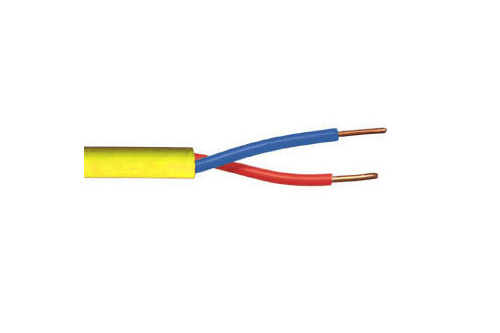

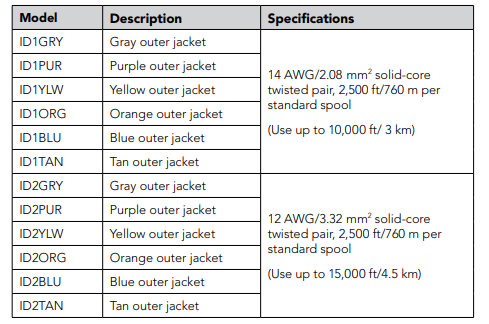

Two-wire decoder technology permits control of large irrigation systems, over

relatively long distances, by inserting waterproof decoder modules as needed in a

low voltage, direct burial two-wire path.

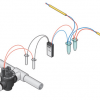

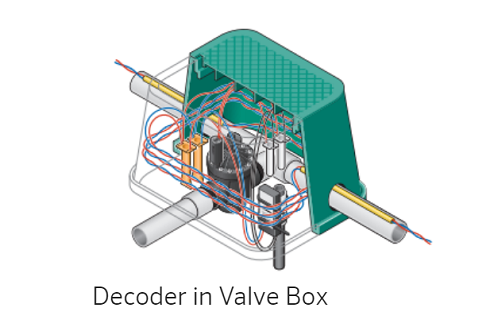

The wire is cut wherever station control is needed, and the decoder wires

are spliced into the path. The decoders are then connected to local

standard 24 VAC solenoids for individual operation of valves and

similar devices.

Each decoder is uniquely addressed, and both the signal for their address, and the power

required for solenoid operation, are sent over the single pair of wires. Up to 99 decoders

can be individually operated over a single pair of wires in this manner.

Benefits:

- Decoder systems save wire. The greatest attraction to many users is the ability to operate 99 stations with only two wires

(usually 14 AWG/2.08 mm2

solid copper), instead of 100+ wires. They can also save connectors and labor associated with

large numbers of individual wire runs.

• Decoder systems are flexible. As long as the two-wire path is reasonably

accessible throughout an irrigation system, stations can be added later

by inserting additional decoders into the path at any point, with minimum

disruption of turf and landscape. Decoder wire runs can even be spliced

and tee’d to follow pipe trenches and minimize wasted wire.

• Decoder systems are electrically efficient. They have the ability to operate

large numbers of solenoids over relatively long distances.

» With 14 AWG/2.08 mm2

solid wire, a controller can activate solenoids up to 10,000 ft/3 km away (metric diameter

based on commonly available wire sizes in international markets. IDWIRE1 is technically 1.63 mm diameter, or 2.08

mm2

area).

» With 12 AWG/3.3 mm2

dia. wire, they can operate up to 15,000 ft/4.5 km. Longer runs are possible with even heavier

wire, but not practical.

» The ACC family of decoder controllers provides up to 6 two-wire paths to the field. Therefore, a controller can

operate up to 15,000 ft/4.5 km in each of 6 different directions.